MANUFACTURING

A POWERHOUSE IN CRAFTING THE FINEST

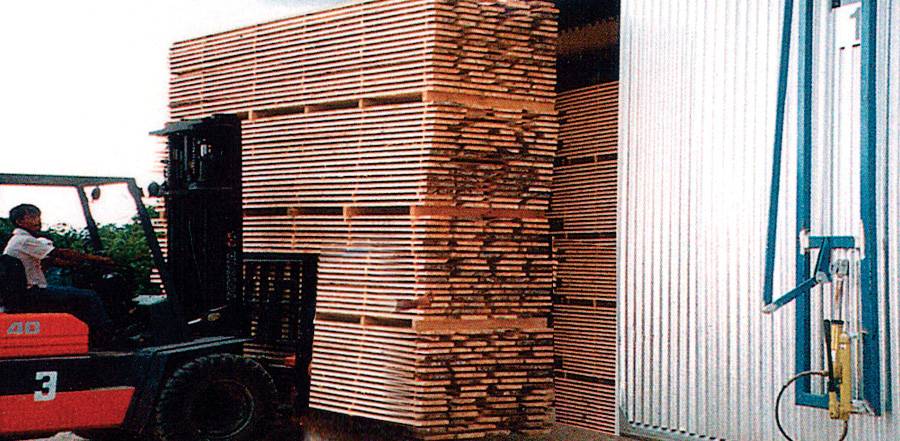

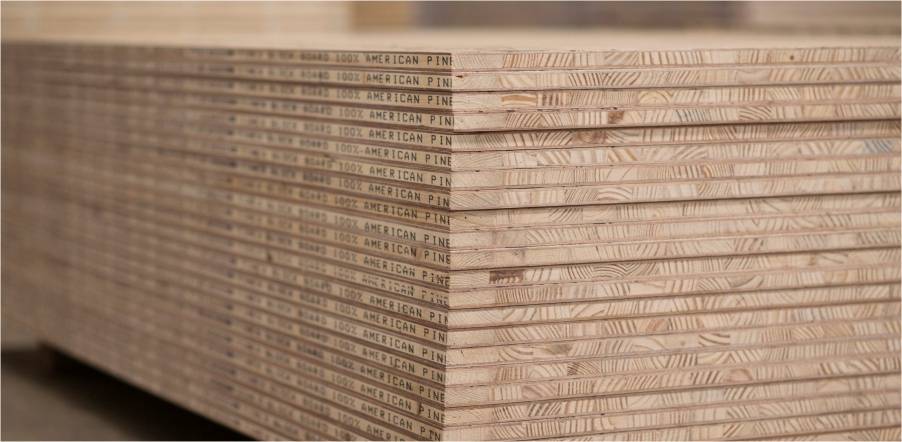

Timex has consistently delivered excellence in plywood products with a state-of-the-art manufacturing plant spanning XXX thousand square feet at Vapi, Gujarat. The company’s initial focus on manufacturing plywood products allowed it to perfect its craft and establish itself as a trusted brand in the industry. Timex Plywood has always been committed to sourcing wood and raw materials of the highest quality from across the world to ensure the finest quality products.

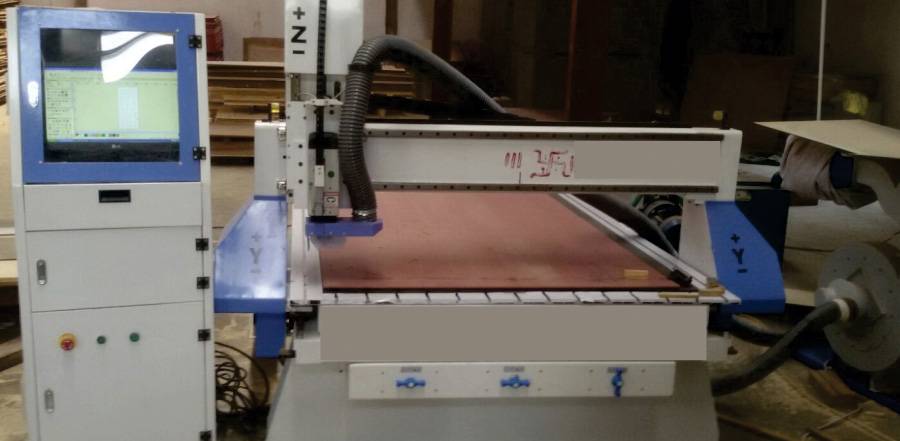

One of the reasons for Timex Plywood’s sustained success is the highly advanced and precise manufacturing equipment used in our production process. The advanced machinery and equipment range includes a sawmill, computerized seasoning kiln, vacuum pressure impregnation tank, hot press, veneer dryer membrane press, Italian an calibration machine, German panel saws, wide-belt sanding machine from the Netherlands, spray booth, edge-bend machine, CNC machine, among other.

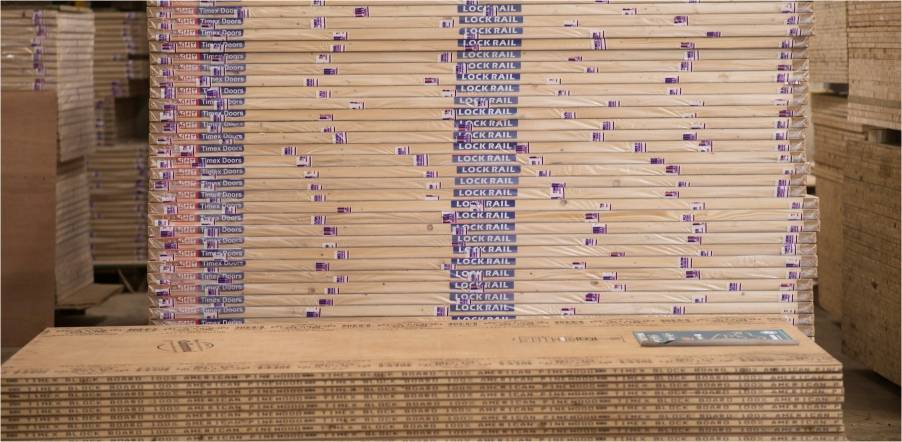

The company employs a highly skilled and continuously trained team that is well-versed in operating these machines to ensure that our products are of the highest quality. The company has the capacity to produce XX million square meters of plywood annually and has a strict quality control system in place to ensure that every product is of the highest quality.

Timex Plywood Company has established itself as a leader in the industry with a state-of-the-art manufacturing plant, sourcing of high-quality raw materials, advanced manufacturing equipment, a skilled team, and a strict quality control system. We’re committed to delivering products that meet international standards and have equipped ourselves with all the necessary approvals. Our advanced in-house R&D team is continuously working towards developing innovative and improved products. The company’s vision for the future includes exciting offerings, better products, and better costs.